Innovive offers multiple water bottle solutions, including pre-filled acidified water bottles. We follow a strictly controlled multi-step water formulation process to ensure that bottles are filled with the highest quality water for your animals.

Our process includes:

- Highly regulated multi-step water formulation process

- Water quality tests performed on each batch

- Adherence to strict quality standards before delivering water to our customers

Innovive Water Formulation Process

The water first passes through an activated carbon tower, a water-softening system, dual pre-filters, and Reverse Osmosis (RO) membranes. Afterward, the RO water goes through additional micron filters, onto UV sterilization, and then undergoes an ozone oxidization process. The ozonated water then passes through a .35 micron filter before filling into bottles.

Fig. 1 – Innovive Water Formulation Process

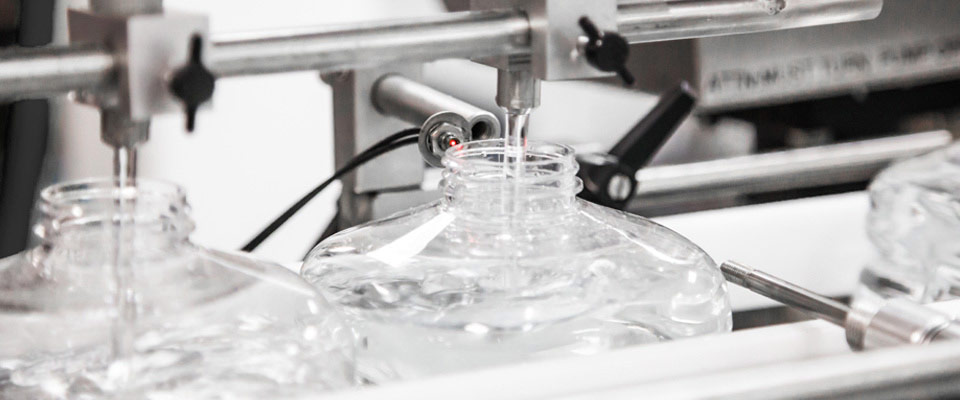

The filling of Aquavive® water bottle occurs within a positive-pressure HEPA-filtered environment. An automated conveyor system fills, caps, dates and labels the bottles. The water is acidified to a range of 2.5 to 3.0 pH before capping. The filled bottles are then packaged in an inner vacuum bag and a secondary containment outer bag for maximum security.

Quality Testing and Standards

Innovive performs consistent water testing to ensure it meets our quality standards before bottles are shipped to facilities. Our water is tested for HPC, TOC (total organic carbon), mold, coliform, and yeast. Customers can trace back to these test results using the date and time stamped on each bottle or the lot number affixed to the pallet.

Previous: Secure Process

Previous: Secure Process